Post by Atomic Addiction on Jan 20, 2010 0:56:08 GMT -5

I just posted this on my blog but thought I would throw it up here also...

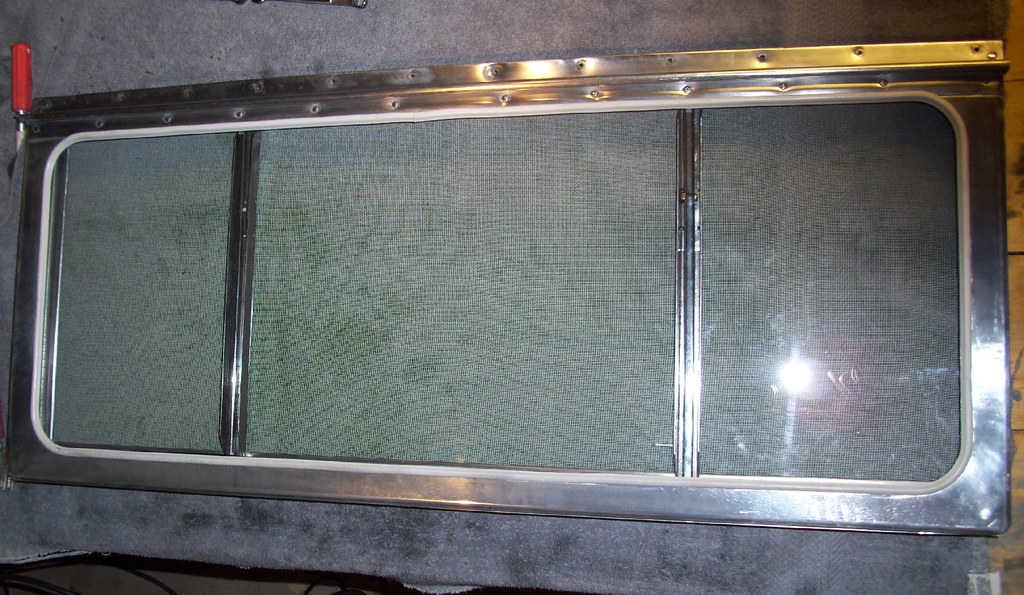

I got an rear window replacement for the trailer. The "new" window is from a trailer that was burned out. The poor old window took quite a beating. I don't know if the heat made the window aluminum super-oxidize or not but it is A LOT worse than most I have seen. There is a thick scale and soot (I'm guessing) on all of the parts. It smells like a camp fire. The inner parts are a lot worse than the outer. See for yourself...

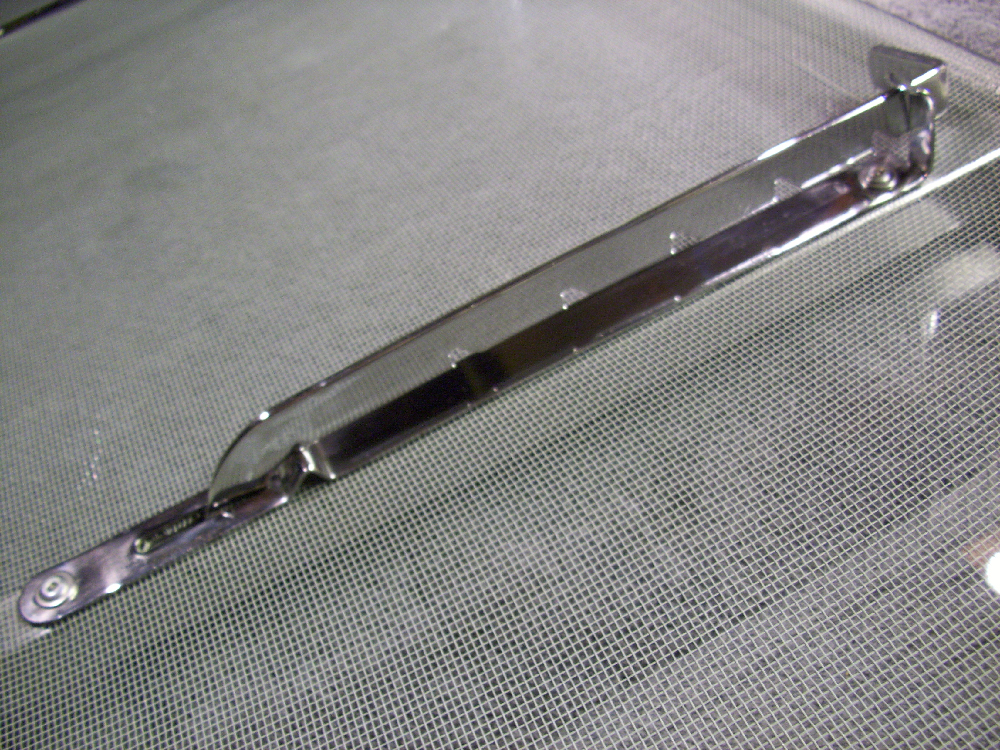

You can barely see the spring plate. It is in there somewhere...

started taking the window apart. Of course there were snags. The screw where completely rusted together. I didn't want to wait on a penetrator to do it's magic so I went to work with a Dremel...

This is what you get for your troubles. A cap full of busted screws. I ordered new screws from Vintage Trailer Supply they should be here soon.

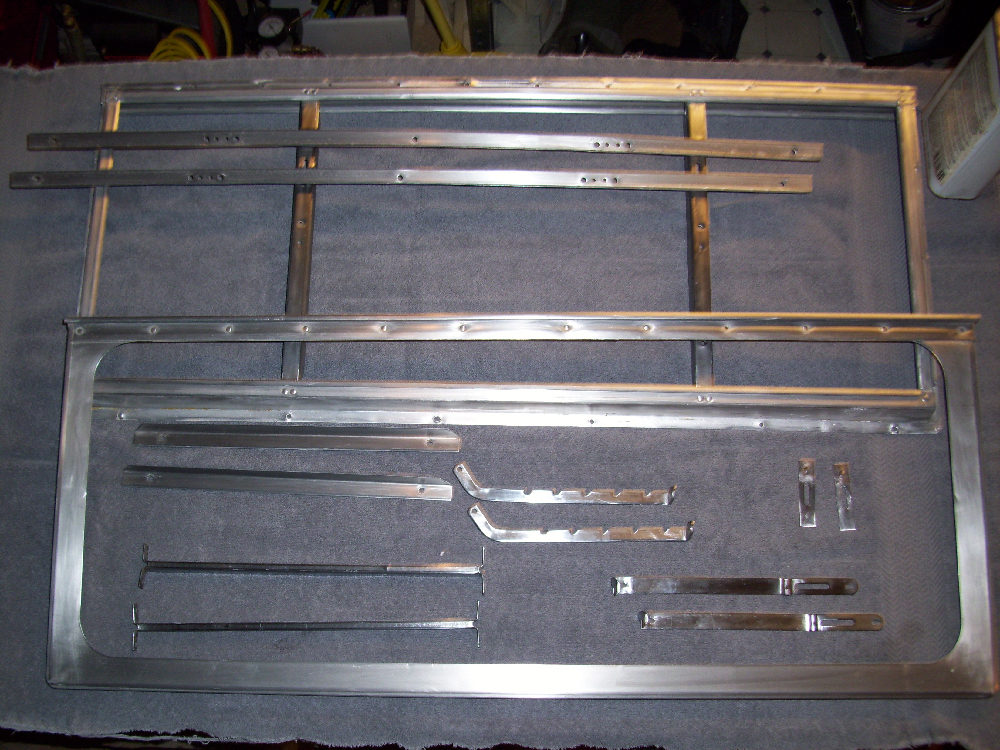

Who knew there were so many parts to these windows?

You can see the nasty parts are now disassembled...

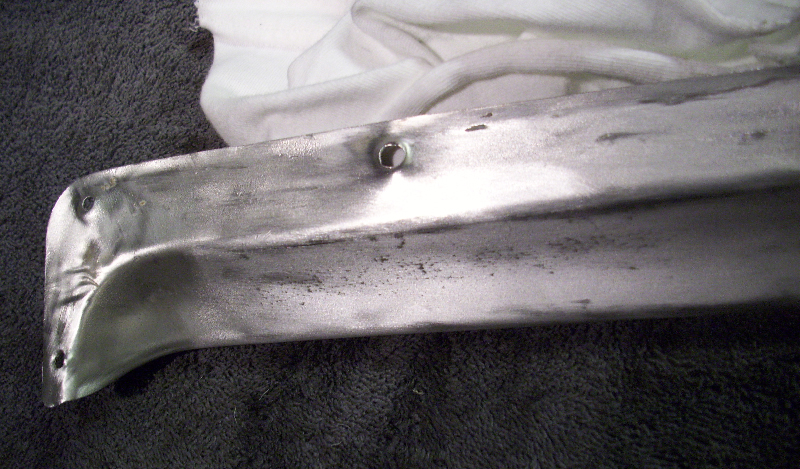

Parts of the frame where pretty bent up...

I used my pliers to straighten them out...

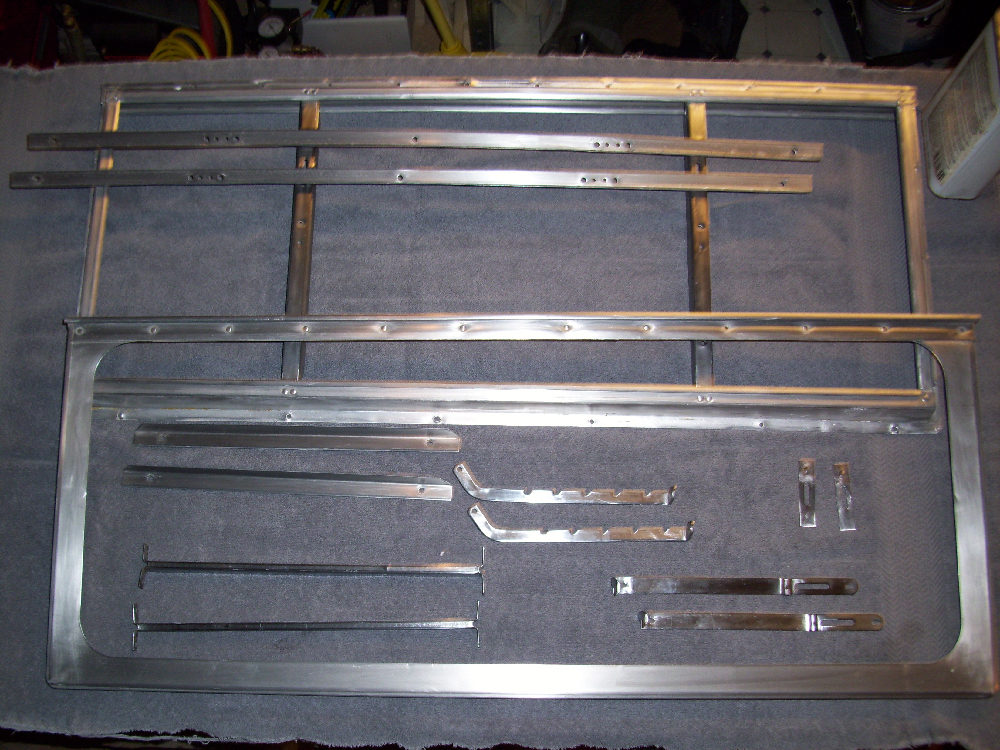

I started cleaning and refinishing all of the parts. I used 250 grit sandpaper, a fine wire wheel, a green scotch brite pad, mineral spirits and steel wool to really try to remove all of the crap. It took a very long time to cut through it. Of course all of those abrasives really messed up the aluminum finish. I then went to work wet sanding all of the pieces. I started with 320 grit working my way up to 1500 grit. I used 320, 400, 600, and 1500 grit waterproof sandpaper from Gator Finishing Products. Here is the results from about 10 hours of wet sanding...

You can see it is quite of a improvement. There are bunch of swirl marks and tiny scratches in the finish. However it is a great jumping off point for the polish...

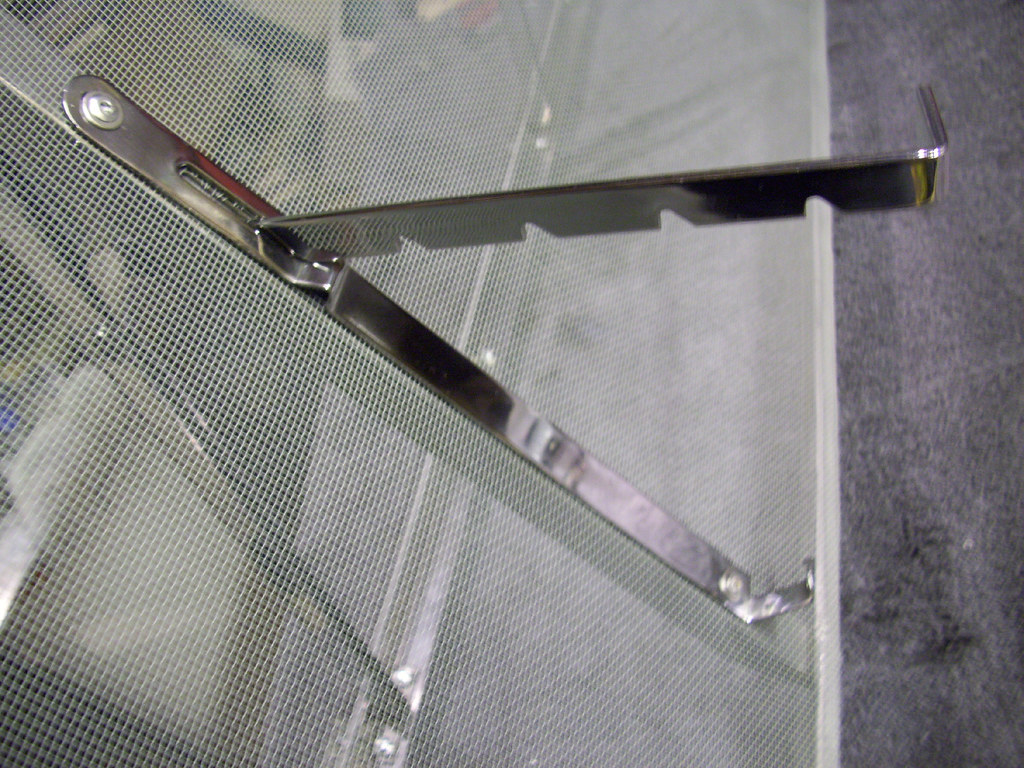

My polishing supplies came today from Caswell Plating. Here is the result from a bit of trying out the polish on the lifter arms. The one on the left is wet sanded and the one on the right is polished...

Maybe you can see the reflection of the camera in the polished lifter arm?

It is not perfect but then again it is a world of difference than what I started with. The finish would also be better if the parts were better to begin with. I'm happy with it. I think I have about 18 hours or so in this window and I'm not done yet. More polish and reassembly. Yeah, I know what you are saying.."Are you out of your mind? At this rate you won't be done until 2025." Yes and no... For one I want to do it right the first time. Why not? I won't have to touch this window for quite sometime. I shouldn't have even half of the issues with the rest of the windows in our trailer. Those windows should be a quick wet sand and polishing.

Like I said, still more work to do in the polishing department. I have to get a new piece of glass cut for it and I'm waiting on a package from VTS. Then reassembly with new gaskets and seals. I will keep you all up to date on any progress.

I got an rear window replacement for the trailer. The "new" window is from a trailer that was burned out. The poor old window took quite a beating. I don't know if the heat made the window aluminum super-oxidize or not but it is A LOT worse than most I have seen. There is a thick scale and soot (I'm guessing) on all of the parts. It smells like a camp fire. The inner parts are a lot worse than the outer. See for yourself...

You can barely see the spring plate. It is in there somewhere...

started taking the window apart. Of course there were snags. The screw where completely rusted together. I didn't want to wait on a penetrator to do it's magic so I went to work with a Dremel...

This is what you get for your troubles. A cap full of busted screws. I ordered new screws from Vintage Trailer Supply they should be here soon.

Who knew there were so many parts to these windows?

You can see the nasty parts are now disassembled...

Parts of the frame where pretty bent up...

I used my pliers to straighten them out...

I started cleaning and refinishing all of the parts. I used 250 grit sandpaper, a fine wire wheel, a green scotch brite pad, mineral spirits and steel wool to really try to remove all of the crap. It took a very long time to cut through it. Of course all of those abrasives really messed up the aluminum finish. I then went to work wet sanding all of the pieces. I started with 320 grit working my way up to 1500 grit. I used 320, 400, 600, and 1500 grit waterproof sandpaper from Gator Finishing Products. Here is the results from about 10 hours of wet sanding...

You can see it is quite of a improvement. There are bunch of swirl marks and tiny scratches in the finish. However it is a great jumping off point for the polish...

My polishing supplies came today from Caswell Plating. Here is the result from a bit of trying out the polish on the lifter arms. The one on the left is wet sanded and the one on the right is polished...

Maybe you can see the reflection of the camera in the polished lifter arm?

It is not perfect but then again it is a world of difference than what I started with. The finish would also be better if the parts were better to begin with. I'm happy with it. I think I have about 18 hours or so in this window and I'm not done yet. More polish and reassembly. Yeah, I know what you are saying.."Are you out of your mind? At this rate you won't be done until 2025." Yes and no... For one I want to do it right the first time. Why not? I won't have to touch this window for quite sometime. I shouldn't have even half of the issues with the rest of the windows in our trailer. Those windows should be a quick wet sand and polishing.

Like I said, still more work to do in the polishing department. I have to get a new piece of glass cut for it and I'm waiting on a package from VTS. Then reassembly with new gaskets and seals. I will keep you all up to date on any progress.

See my rebuild pics at:

See my rebuild pics at: